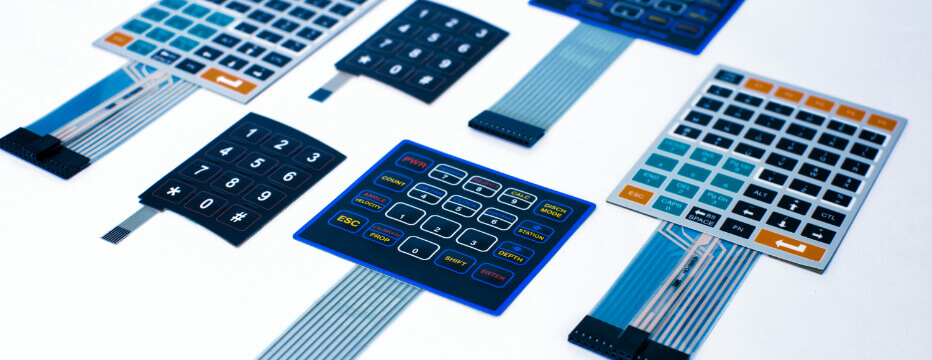

The slimmest, most flexible membrane switches on the market!

Your clients want to use a product that is as practical as it is aesthetic.

Offer them the very best with our membrane switch keypads: budget-friendly, lightweight, and easy to install wherever you need them to be.

Our design and engineering teams will work with you to select the best materials for your application. We manufacture high-quality membrane switches for a variety of industries, including medical, appliances, transport, and industrial. Contact us to discuss your needs.

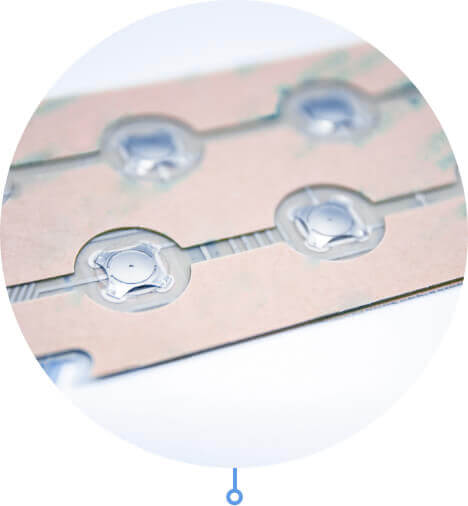

- Graphic overlay

- Adhesive

- Top circuit

- Spacer

- Bottom circuit

- Adhesive

Take your products to the next level with the most reliable membrane switches

6 reasons why you should choose Memtronik as your membrane switch manufacturer

Quick time to market

In less than 48hrs, our team can evaluate your human-machine interface (HMI) project. Our state-of-the-art facilities and seasoned membrane switch design experts will then deliver a product that meets all of your expectations in record time. We can also create a small-batch prototype to test your design.

Fully customized design

A membrane switch should never be a limiting factor for your product design . One of the main advantages of using this technology is that it can adapt to almost any application. Material, size, thickness, type of adhesive… all of the factors that come into play when manufacturing your HMI will be selected based on your requirements.

Traceability and compliance with UL 94, NEMA, and IP standards

All of the membrane switch keypads we manufacture comply with the highest quality and safety standards. They respect the requirements outlined in the UL 94 standard concerning the flammability of plastic components installed in appliances, the IP standard that measures a product’s sealing, and all applicable NEMA standards. Additionally, our traceability policy is second to none.

Endless design possibilities

If you can dream it, we can design it (almost always!). Colourful, metallic, backlit, thermochromic, tactile, curved… Your graphic overlay’s aesthetic is totally up to you. A wide variety of design options are available, so you can create an unparalleled experience for everyone who interacts with your HMI.

High-volume manufacturing

Our all-new factory has allowed us to increase our production capacity even more! We have one of the industry’s most automated and robotized facilities in all of North America. In addition to enhancing the precision and quality of our operations, this technological investment has given us the flexibility required to produce as many (or as few) membrane switch keypads as you need in a fraction of the time.

Simplified prototyping services

An important factor in a product’s success is the efficiency of its HMI, so it’s usually a good idea to test out your membrane switch design early on in the development process. Our flexible approach allows us to quickly create a small batch of prototypes that you can share with your team, or even your target users!

Products that are built to last, even under extreme conditions

The membrane switch has been perfected over a number of decades, yielding a modern HMI that is renowned for its durability. Exceptionally slim and flexible, it can do its job even in the harshest of conditions.

Depending on the material, your membrane switch keypad’s lifespan can range from thousands to millions of interactions. All you need to do is choose components that are perfectly aligned with your product’s application – our expert engineers will be there to guide you through the decision making process.

Prolonged exposure to moisture: immersion, condensation, or vapour

Contact with irritants: abrasives, chemical products, and vibrations

Heat and sunshine: will not get deformed and is resistant to UV rays

Endless design and development options!

-

Backlighting

Add another dimension to your membrane switch with LEDs or fiber optics.

-

Electroluminescent panel

The gold standard in lighting: perfect distribution!

-

Support plate

Integrate a rigid plate behind your keyboard using aluminum, polycarbonate, or acrylic.

-

Flexible circuits

The flexibility of printed circuits means they can be installed on a curved surface.

-

Graphic overlay finishes

Anything is possible: glossy, anti-reflective, textured, mirror effect, metallic effect, faux stainless steel…

-

Design materials

For interior or exterior use. Do you require antimicrobial materials?

-

Manufacturing options

Take your pick: colours, raised embossed keys, thermochromic or photochromic inks, etc.

-

Connector options

Adapted according to your product: male connector, female connector, soldered, or ZIF.

-

Circuit protection

We are able to ingrate ESD, EMI, and RFI protection.

Questions about membrane switches?

Customized membrane switches

Do you have very specific requirements? Our experts will be able to point you in the right direction.

Get a quote in less than 48 hours

Experience our efficiency and unbeatable prices firsthand!

For more expert advice,

check out our latest publications!

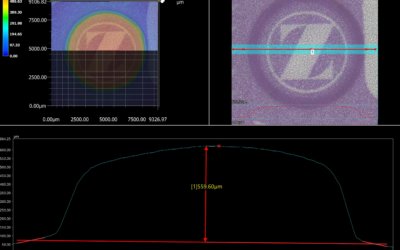

An inside look at the manufacturing process of a high-precision overlay for the medical industry

When it comes to human-machine interfaces (HMIs) intended for the medical and pharmaceutical sectors, state-of-the-art technologies are vital to the manufacturing process. After all, achieving superior reliability and precision is the ultimate goal! Strict standards...

How to ensure your product is optimized and meets your needs

Whether you’re at the prototyping stage, the scaling stage or during production, Memtronik can offer you a combination of tests and trials to evaluate the performance of your product, or to monitor certain parameters with these 5 types of laboratory trials. Why should...

How to choose an eco-responsible manufacturer

For many companies, when it comes to choosing a manufacturer for your projects, eco-responsibility is a very important criterion. Whether it is in terms of infrastructure, production, processes, or supply methods, which measures does your potential partner take to...