All about membrane switch components

What makes the membrane switch such a durable, flexible, robust solution? One of its major strengths is the simplicity of its components, all of which leave lots of room for customization.

In the hands of expert manufacturers, membrane switch components come together to create an extremely reliable human-machine interface (HMI) that can accommodate almost any design constraint under the sun!

Graphic overlays

True to its name, a graphic overlay is a membrane switch component you can see. More specifically, it serves as the interface between user and machine. Design and durability are therefore two extremely important elements when creating a graphic overlay. It needs to hold up against external conditions – usage, humidity, heat, corrosive cleaners, etc. – while providing a pleasant user experience.

Depending on how durable it needs to be, a graphic interface can be made of polycarbonate, polyester, or acrylic. A number of functional and aesthetic elements can also be added on, and its thickness can vary to provide more or less sensitivity based on the intended tactile experience.

Adhesives

It would be easy to dismiss this part of the design process – choosing a glue isn’t exactly rocket science! But when you realize that its job is to attach a graphic overlay to the underlying circuitry, and then the keypad to the machine, it’s easy to understand why adhesives play an essential role in the membrane switch’s resistance to external conditions. Based on the surface, materials, desired performance, and even appearance, the ideal adhesive will vary.

At Memtronik, the adhesives we use during the membrane switch manufacturing process are far from ordinary! We print them directly onto the circuit, which increases the quality of our products while significantly reducing the cost.

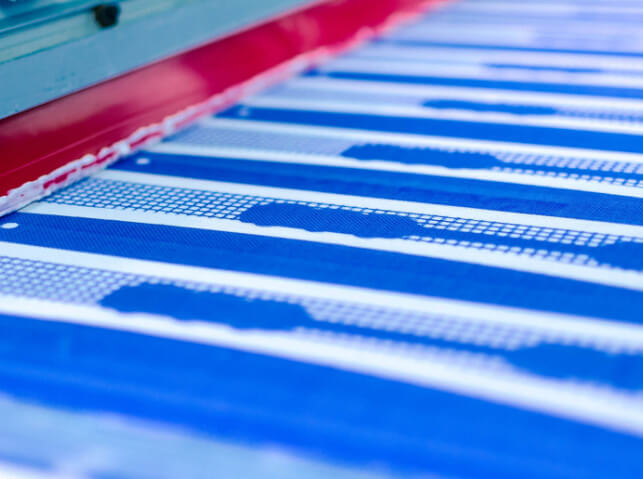

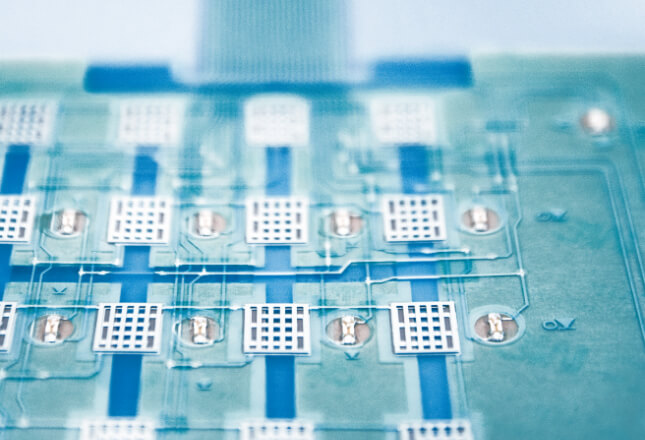

Circuits and spacers

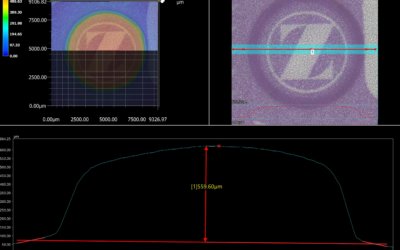

The most important membrane switch components are its two printed circuits and its spacer. When you press a key on a membrane switch, the associated segment of the upper circuit makes contact with the lower circuit, creating a connection that sends a signal to the machine.

These circuits and spacers can be printed on different types of materials, so they can adapt to the specifics of the machine on which the keyboard will be installed.

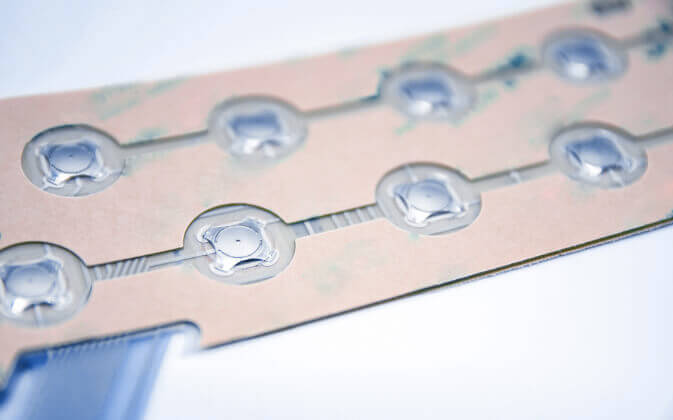

Metallic domes

Depending on the product type, you can add a membrane switch component that offers tactile feedback for the user. This component generally takes the form of a metallic dome inserted between the two circuits, creating resistance that allows the user to confirm that they have successfully pressed one of its keys. In some cases, this tactile feedback can improve the user experience. Most domes have a lifespan of approximately 3 million presses.

Custom options

With Memtronik, you can customize and personalize any of the above-mentioned membrane switch components according to your needs. For example, you can integrate backlighting using LEDs or an electroluminescent panel . We can also integrate a support plate, which is a rigid plate made of aluminum, polycarbonate, or acrylic that sits behind your keypad.

Quote within 48hrs

From very complex challenges to quick little projects, our team can handle it all. Tell us about your product and we’ll get back to you with a game plan in less than two days!

Learn everything you need to know about membrane switches

Graphic overlays

Colourful, metallic, embossed, or minimalist – the only limit is your imagination.

Custom membrane switches

Do you have highly specific requirements? We can design a fully personalized interface for you.

Membrane switch prototypes

For complete peace of mind, test a small batch of your membrane switches before taking your design to production.

For more expert advice,

check out our latest publications!

An inside look at the manufacturing process of a high-precision overlay for the medical industry

When it comes to human-machine interfaces (HMIs) intended for the medical and pharmaceutical sectors, state-of-the-art technologies are vital to the manufacturing process. After all, achieving superior reliability and precision is the ultimate goal! Strict standards...

How to ensure your product is optimized and meets your needs

Whether you’re at the prototyping stage, the scaling stage or during production, Memtronik can offer you a combination of tests and trials to evaluate the performance of your product, or to monitor certain parameters with these 5 types of laboratory trials. Why should...

How to choose an eco-responsible manufacturer

For many companies, when it comes to choosing a manufacturer for your projects, eco-responsibility is a very important criterion. Whether it is in terms of infrastructure, production, processes, or supply methods, which measures does your potential partner take to...